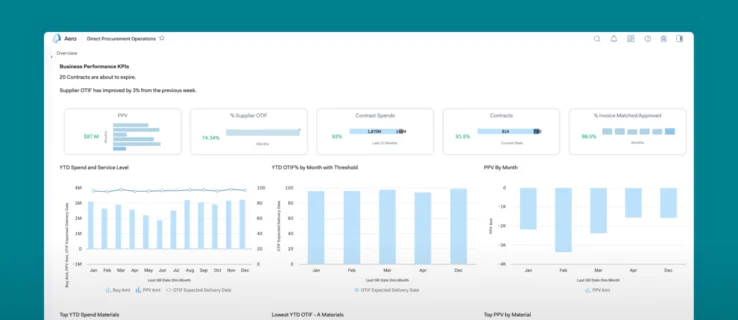

Spend Optimization

Gain visibility into procurement spend to uncover savings and drive efficiency.

Understands

Analyzes spend across categories, suppliers, and regions to detect inefficiencies.

Recommends

Identifies consolidation, cost-saving, and negotiation opportunities.

Acts

Automates spending adjustments, sourcing decisions, and prioritization of savings initiatives.

Learns Continuously improves optimization logic by learning from outcomes to reduce total procurement costs, improve category-level efficiency, and maximize ROI on supplier spend.

Learns

Continuously improves optimization logic by learning from outcomes to reduce total procurement costs, improve category-level efficiency, and maximize ROI on supplier spend.