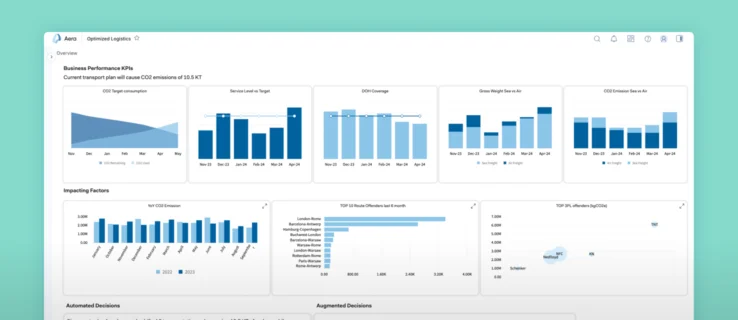

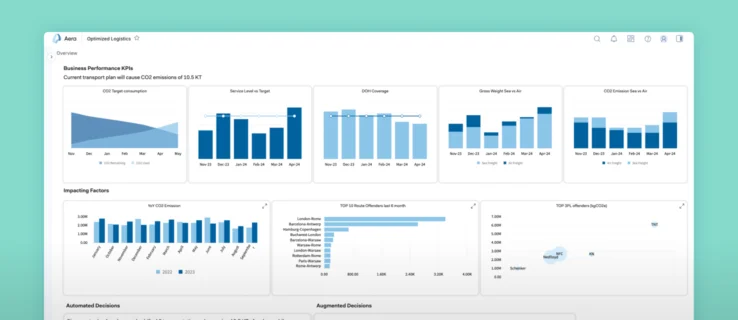

Carbon-Footprint optimization

Monitor supply chain activities in real time to flag deviations from carbon targets and trigger corrective actions.

Understands

Tracks emissions across transportation routes, manufacturing processes, and distribution networks against sustainability targets.

Recommends

Identifies high-emission activities, alternative sourcing options, and route or mode changes to reduce carbon footprint.

Acts

Automatically flags carbon-target violations, triggers sustainability reviews, and initiates low-carbon alternative workflows.

Learns

Continuously improves carbon optimization by learning from outcomes to reduce overall carbon emissions, improve compliance with sustainability commitments, and trigger decarbonization strategies.